In this Hi-tech world, technology and organizational practice are refining. Industries need the standard practices and applications for asset management which stands the organization in a strong position, in this competitive world. So the enterprise with the latest development in asset management is implementing standard practices in the organization with the help of an Enterprise Assets Management solution.

It’s the dawn of the age of smart assets.

“The radical transformation in asset management that cutting-edge technologies have brought, make the assets more productive and minimize the cost is maintained”

It signals, the new technologies are revolutionizing supply chains, retailing, and customer support, and dramatic changes are taking place in the world of asset management, whether fixed or mobile.

Why is Enterprise Assets Management introduced in the industry?

Failure of critical equipment in capital-intensive industries leads to disruptive and expensive labor, in-process materials, and customer dissatisfaction. Regulated industries that are ignoring FDA need to track records for process maintenance with an audit trail. At the same time, personal safety is a vital issue including compliance with occupational and environmental safety regulations. Organizations recognize these issues and engagement of a maintenance organization to sustain their assets. An Enterprise Assets Management (EAM ) system is needed for standardization in the procedures to manage the people, parts, and workflows.

Let’s understand Enterprise Assets Management in a nutshell that Enables Asset Management

Enterprise assets management (EAM) is all about the management of physical assets’ maintenance of an organization during the lifecycle of each asset. It is a systematic procedure of managing the lifecycle of an asset to increase its life, minimize costs, enhance quality and productivity. In an integrated business software package, EAM consisted of an asset register, work order management, inventory, and procurement functions.

Benefits of the EAM system

- Increased visibility in the organization

The critical assets and company resources operated by the EAM enhance the efficiency by the company the right tools to organize its asset portfolio quickly and efficiently. EAM is designed to offer a unified platform for managing physical assets across an organization. EAM introduced standardization, a well-organized way, easily accessible asset information, preventive maintenance (PM) can be scheduled. PM helps company proper assignment, monitoring of their maintenance crew, clear visibility, and traceability to improve the company’s compliance and service level agreements (SLAs).

EAM offers a broad range of robust features to asset performance and costs through the entire life cycle to manage, track and get judgment into your asset performance and costs through the entire asset lifecycle. Thereby, EAM increases the visibility of all company assets through effective reporting and insight and allows a company to identify areas of improvement and excellent performance.

- All-In-One solution

It works on the ‘ALL-IN-ONE’ concept where every employee, every department, and every location’s information is stored in a single place. It also includes- company’s physical assets’ lifecycle costs, maintenance histories, energy consumption, purchase orders, warranty catalogs, and audit records.

EAM solution is used to manage contracts, purchase orders, and requests for proposals (RFPs). Accounting can handle MRO invoices and budgets. Materials managers are used to managing inventory and storerooms/warehouses.

- Integration with SCADA and ERP system

With system integrators, you can integrate EAM with building automation systems (BAS) and supervisory control and data acquisition (SCADA) to get real-time information about energy usage and the condition of assets across all units. EAM can integrate with enterprise resource planning (ERP) systems to assure recent and precision in financial purposes. Business intelligence integration purveys executives an integrated view of asset performance and costs.

How EAM will Transform Organizational Practices?

- From Reactive to Proactive Maintenance Practices

EAM is designed for a preventive approach for maintenance and asset management. The system alarm when assets need maintenance and repairs. Once set up is done, the system can automatically generate work orders, purchase orders, RFPs, and others as per schedules. It ensures to complete the work order on time.

- Go Mobile

Mobile technology is changing asset and cost management to a great extent. EAM system works in the mobile app for iOS, Android, and Windows operating systems to make maintenance and asset management possible on the go. The concerned tech people can analyze and repair histories, access parts catalogs, audit trails, place purchase orders, enforce new work orders, place purchase orders, and more. Its mobile platform tends to transform organizational practices. - Standardize Best Practices

With EAM, you can establish workflows and checklists to set up consistency and standard practices in your highly beneficial organization, especially for condition monitoring, troubleshooting, accounting, and cost management.- Checklist for EAM

- Get Rid of Maintenance Backlog

An increase in operating costs and frequent downtime- is a runaway maintenance backlog, which reduces productivity. It has disabled many organizations that could otherwise operate at maximum efficiency. With an EAM system in place, a maintenance backlog can be a thing of the past. - Improve Health and Safety Practices

Robust health and safety practices are essential for the well-being of the workers, as well as the assets. Modern EAM systems are equipped with powerful health and safety management tools. EAM takes inspection rounds in an automated fashion and keeps an eye on everyone’s safety certification. This ensures that accidents and unplanned incidents won’t occur. - Keep Up with Changing Technology

EAM software incorporates the latest technology trends. The organization should avail latest technologies and get an edge by offering better services and more choices to the clients as well as alleviate the business units that are ineffective and out-of-date processes. - Change Decision-Making Practices

EAM software solutions eliminate the shooting in the dark when it comes to organizational and operational decision-making. It determines the use of adequate ways that help in saving dollars and increasing efficiency, which, in turn, reduces operating costs and also provides various ways to make the practices better.

Who is the winner- EAM vs CMMS

Computerized Maintenance Management System (CMMS) and Enterprise Asset Management (EAM) software work on the same objective. Both solutions have the specific goal of managing, maintaining, and protecting company assets by streamlining and automating maintenance management, inventory management, work order generation, and scheduling. And both systems divert organizations from a reactive maintenance strategy to a proactive one. The comparison of CMMS and EAM is a hard nut to crack in, as each software is unique. CMMS was introduced in the late ‘60’. In large industries, it monitors the asset and conducted maintenance. It’s a demand of time to connect CMMS with extra features to make it work seamlessly in a large organization. So EAM is introduced.

In short, we can say, “Maintainance of system and operation is the main objective of CMMS system and EAM is an expandable comprehensive solution which contains all CMMS functions”

The main functions of a CMMS include:

- Automating maintenance scheduling.

- Managing company inventory and work orders.

- Maintaining an asset tracking database.

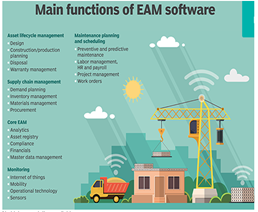

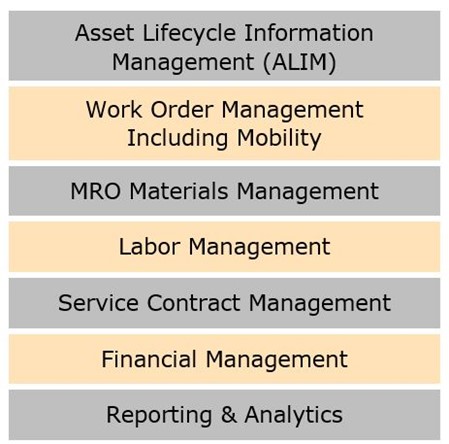

The main functions of an EAM include:

EAM is employed to plan, optimize, execute, and track maintenance activities with related priorities, tools, materials, skills, and information. Asset information, MRO materials, work orders, labor skills, service contracts, finance, and analytics are the prerequisite function of EAM

Looking for software that serves the needs of both- CMMS and EAM?

Promaint is the best-in-class CMMS (Maintenance Management) & EAM software that maintains your assets effectively by managing, tracking, scheduling services, and updating about the status of your assets. Promaint provides better visibility of asset conditions and acts as the catalyst you need for your successful growth story.

Current Enterprise Asset Management Trends

Industrial IoT (IIoT) and analytics are embraced for predictive maintenance globally. When health priority will be a concern, an alert goes to the maintenance planner who prepared a work order to address the issue before it becomes unplanned downtime. Mobile devices allow the tech geeks to simultaneously handle the work order and accomplish the work. This shift from traditional paper to digital devices enhances data quality and ensures integrity. The fusing of the EAM and CMMS system becomes a trusted work planning and execution tool for the management of information, people, parts, and priorities.

If you have any queries, feel free to connect with our business consultants. They would assist you in every way. All the best!